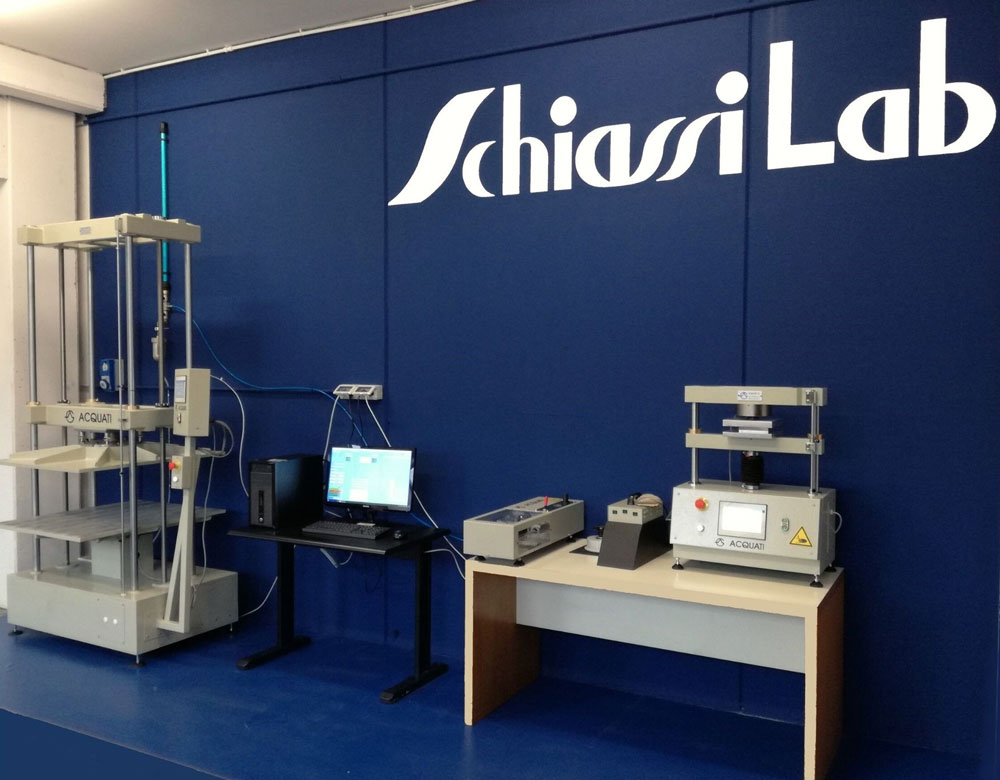

SchiassiLab

We can help you choose the type of cardboard that best meets your needs

How do you choose the best cardboard boxes for your product?

Shipping your product to customers is a delicate phase and, with the choice of packaging, you put your brand and image on the line. It’s therefore a good idea to go for quality.

But how do you find your way around and choose the best cardboard for your products? In Bologna, SchiassiLab offers consultancy, designing boxes made of sustainable and certified cardboard to guarantee a high quality product.

SchiassiLab, Schiassi’s research and development department, was set up to carry our specific laboratory tests and personalise cardboard boxes based on your needs.

Our technologies add value to your product because the production of the boxes is meticulous, correct and tested. Bespoke design means you can choose the best cardboard for your needs.

Our laboratory leaves nothing to chance.

Choosing the correct packaging is crucial as well as a strategic solution.

That is what we guarantee with SchiassiLab.

SCHIASSILAB

We measure the resistance of corrugated cardboad boxes

A series of parameters have to be taken into consideration in the production of a corrugated cardboard box: SchiassiLab aims to provide this consulting service for customers looking for the best solution to their packaging needs.

We provide consultancy based solely on the theoretical aspect but our machinery allows us to get practical.

The choice of raw material is the first step in making the most suitable packaging for your needs. Our analyses and the parameters analysed are based on this.

SCHIASSILAB

Grammage and type of cardboard

Grammage means the weight of a 1 square metre sheet of cardboard. So, depending on the model chosen (number of sheets, flutes), this parameter changes and the resistance will also change accordingly. However, it’s not the thickness that makes the difference.

There are different types of corrugated cardboard with specific flute heights and coefficients, each with its own characteristics, each able to offer the packaging a specific performance.

Specific laboratory tests are carried out on both the finished packaging and the material used to make it; that is, the corrugated cardboard.

SCHIASSILAB

Box compression test

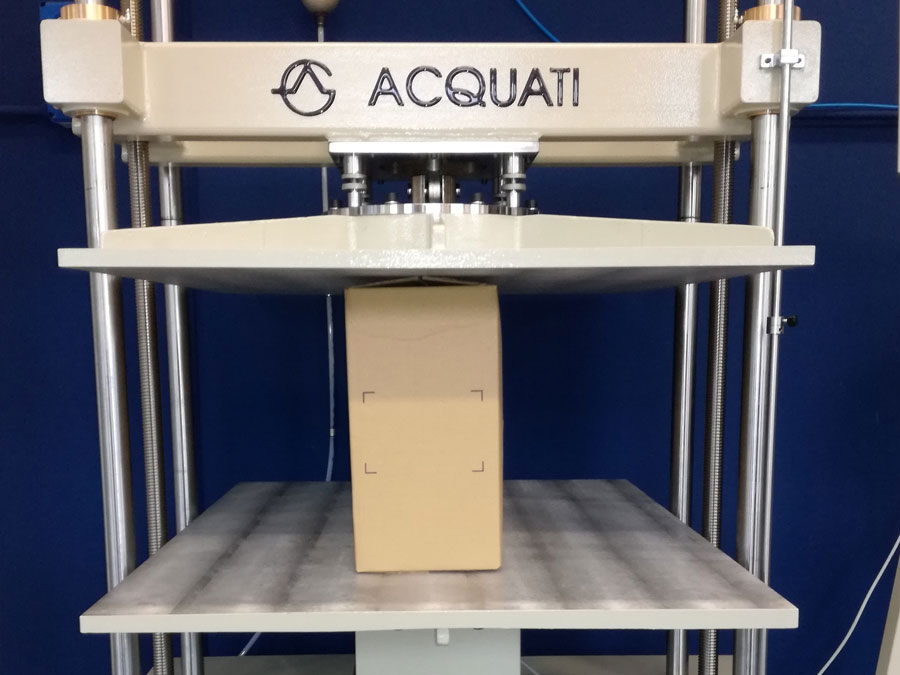

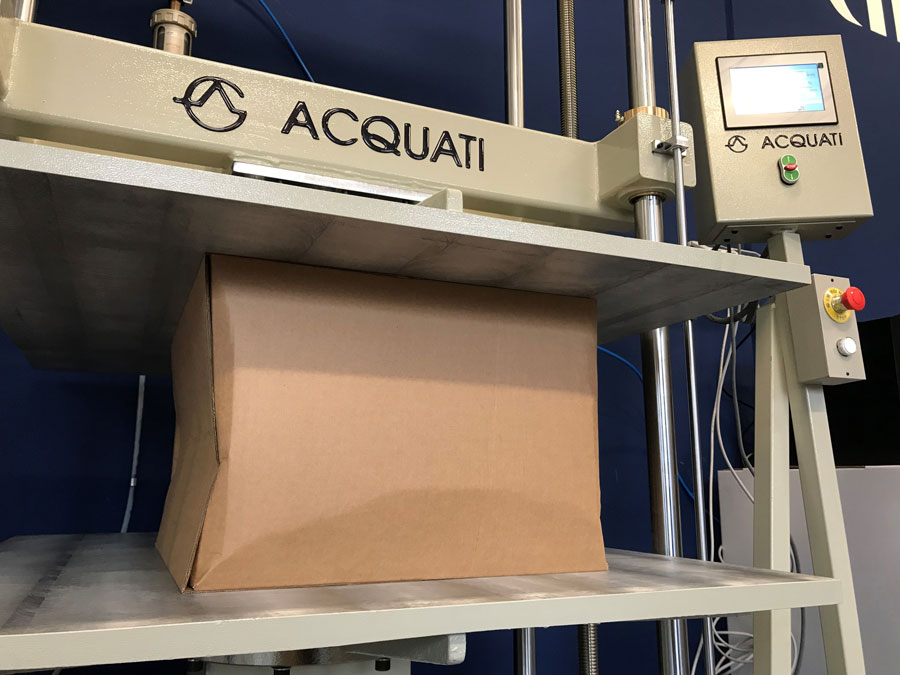

The values that are fundamental in choosing the boxes are the capacity to withstand vertical pressure and stacking.

In this way each packaging can be designed to avoid

problems (such as, collapse) linked to the choice of an unsuitable raw material.

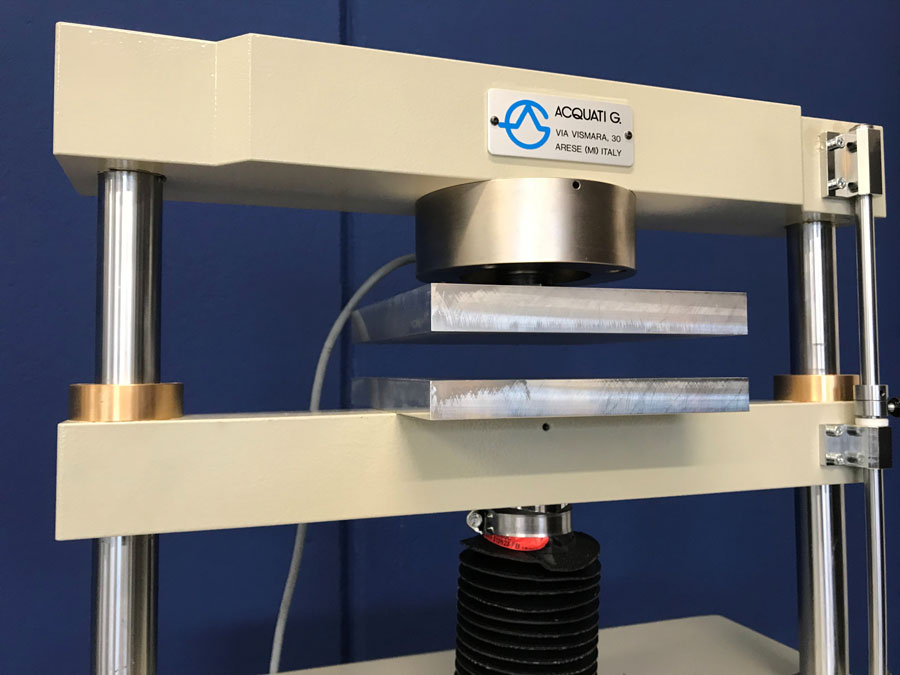

Technology helps and thanks to special machinery, such as the

mini press for the ECT control (Edge Compression Test), tells us

after how many kilograms the cardboard will start to lose its shape (thus identifying resistance to vertical pressure).

We also use a Compression Tester that tests resistance to stacking by measuring the box’s BCT (Box Compression Test).

This compression test analyses the design of the box taking into consideration:

This technology enables SchiassiLab to identify the load bearing strength and the resistance of the packaging, certifying the exact value and so the production of the corrugated cardboard can be increasingly personalised.

With SchiassiLab you will have quality control and personalised consultancy for yout corrugated cardboard

Quality control

SchiassiLab was set up with the aim of certifying the quality of our products: the laboratory is available to customers who need to carry out empirical tests of the strength of the packaging and products before placing them on the market.

The state-of-the-art machinery allows immediate measurement and certification of the quality and compliance of each prototype or packaging leaving the factory

Personalised technical consultancy and assistance

Assess the composition of the raw material, the type of packaging and its palletisation along with our engineers.

We will make a prototype, inspect it and test it.

This will allow us to show you the finished product immediately at the end of our meeting.

Or our technical office, after listening to your needs, will develop a 3D project and will provide you with an animated demo of the made-to-measure packaging with a graphic preview of any requested personalisations.

Make your packaging unique and get noticed on the market, add value to your product, strengthen your brand identity and promote your brand.

Choose the best box, contact our consultants.